Business Card Making Process

The small business card seems simple, but it is quite troublesome to make. It takes many processes to get to your hands. You may want to understand the process of making business cards. The following Business Card Cutter Supplier can give you a detailed introduction.

First, printing options

You have to choose the printing method of the business card, you must also choose the number of times the business card is printed, which is also the color to be printed on the business card. The color of a business card is also one of the important indicators for determining the price of a business card. At the same time, you also have to choose whether to print single-sided or double-sided business cards. The increase in the number of printed surfaces means an increase in the number of times of printing, which also means an increase in color and price.

1. Color selection: Business card colors can be divided into single color, two-color, color and true color to determine different printing times.

2. Single and double-sided selection: Single and double-sided selection of business card printing is the choice of the number of printings. The number of printed business cards is directly related to the price.

Second, Business card content

When you want to print a business card, you have to decide what to print on the business card. The main body of a business card is the information provided on the business card. The business card information is mainly composed of text, pictures (patterns), and unit logos. Digital information is also one of them, but it cannot constitute the mainstream of business cards.

1. Information selection: The text message contains the name of the organization, the name of the business card holder, the title and the contact method. Some business cards also have business scope, multiple text choices, unit motto or auspicious words.

2. Logo selection: If the organization user has his own company logo, most of them need to print a business card.

3. Picture selection: You can also choose to print personal photos, pictures, shades, calligraphy works and simple maps on your business card to make your business card more personal. If you use offset or laser printing, you don't need to consider the size of the picture; if you use screen printing, because the simple screen printing has a lower resolution, it is recommended to use a larger picture.

Third, business card printing

There are currently three main types of business card printing. The simplest is laser printing, followed by offset printing, and screen printing is the most complicated. Laser printing and offset printing are currently widely used, while screen printing is relatively rare.

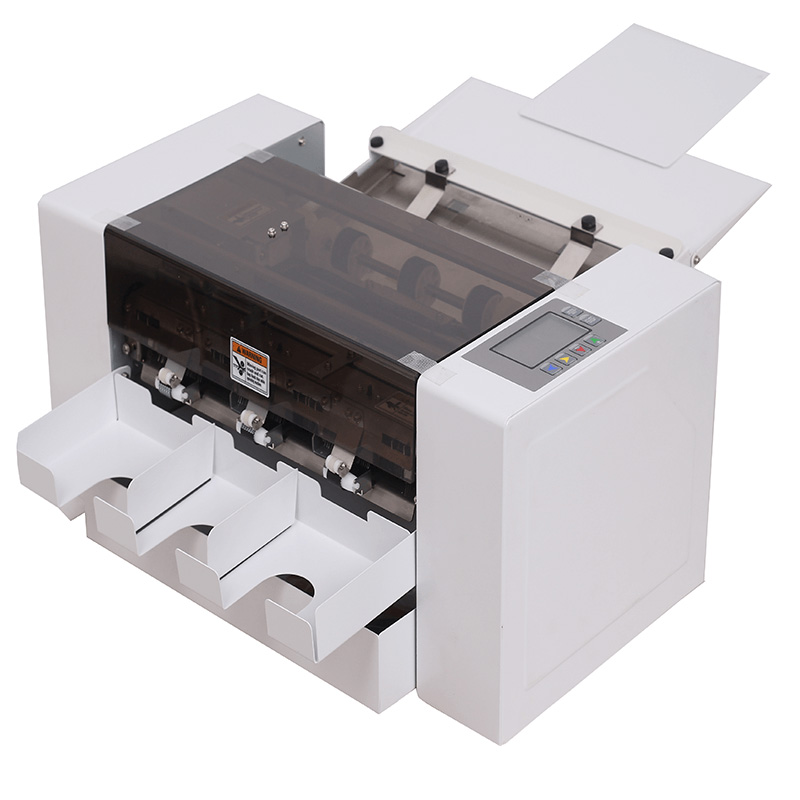

Business Card Cutter

Fourth, post-processing

Post-processing of business cards is mainly computer business card paper, because its large-format and low-thickness paper cannot be used immediately, and it must be post-processed such as plastic, die-cutting, bronzing, and boxing.

1. Plastic Sealing: Low-thickness computer business card paper must be thickened. At present, the only way is to use plastic sealing.

2. Cut card: Cut the plastic business card paper into business cards using Business Card Cutter. Current computer business cards need to be cut into cards before they can be used normally. Business card cutting is an important process in the making of computer business cards.

3. Hot stamping: Many customers of computer business cards and offset printing business cards require a logo or company name for hot stamping. The hot stamping is the last process in business card printing.

4. Drumming: At present, many characters or graphics on business cards use the drumming process to achieve the effect of crystal drumming. This process is achieved by melting the resin powder adhered to the text using a letter printing machine.

5. Indentation: Use an indentation machine to emboss the text or graphics on the business card into protrusions or depressions. This craft business card is a special craft.

6. Die-cutting: The die-cutting process uses a Die Cutting Machine to die-cut business cards. Due to the different shapes of the die, different shapes of business cards are realized.

7. Packing: After the business card is made, it is packed into a special business card packaging box to complete the whole process of making the business card.

8. With the development of society and the needs of customers, imitation gold business cards have appeared, which is different from bronzing business cards.

The above is the process of making business cards.

Comments

Post a Comment